Breaking the monopoly crisis, Sensor Nobleman bravely takes on the heavy responsibility.

2022-10-19

|

China’s journey toward industrial upgrading is long and fraught with challenges. From semiconductor chips and materials technology to EDA tools and sensors—whether in software or hardware—China faces severe, multifaceted, wide-ranging, and multilevel challenges. Many cutting-edge, high-precision technologies and equipment remain “choked” and stuck in a critical bottleneck situation.

In fact, China’s sensor industry has long been under the “dual monopoly” of technology and markets held by Western developed countries. Currently, China can produce only about 7,000 types of sensors—accounting for just one-third of the global total. The severe shortage of sensor chip manufacturing technology has left many Chinese sensors heavily reliant on imports for an extended period. In particular, there is a significant gap between China’s capabilities in mid-to-high-end sensor technologies and domestically produced products; imports of high-end sensor chips now exceed 90%. At a time when Industry 4.0 and intelligent manufacturing are rapidly gaining momentum, this situation will only become more acute. The more we rely on imports, the deeper we’ll become trapped in technological dependency.

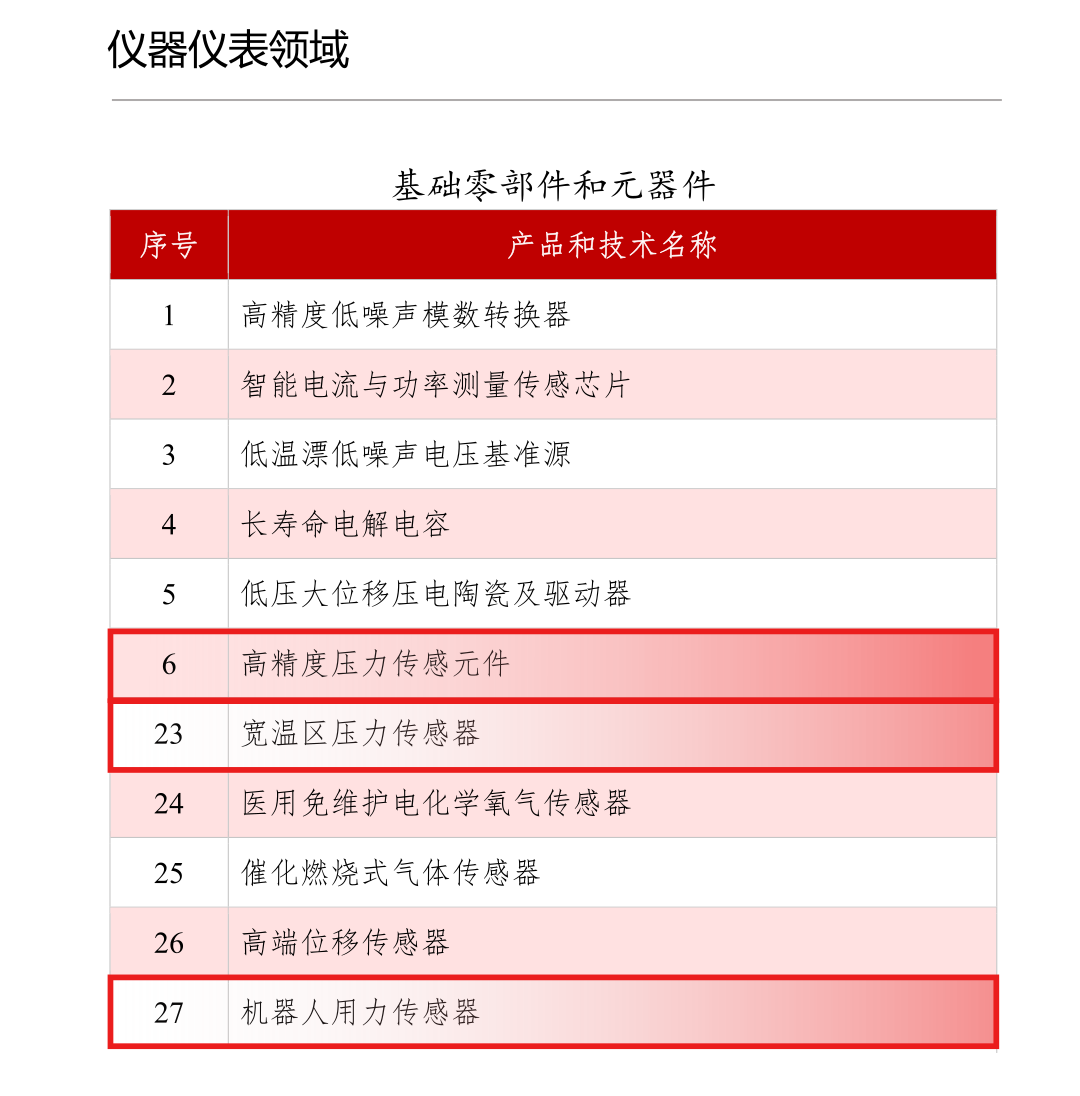

High-end, cutting-edge technologies cannot be begged for nor bought. In the sensor field, China’s primary goal remains achieving domestic production of core components. The “Catalogue for Innovation and Development of Industrial Foundations” (the “Five Industrial Foundations”) compiled in 2022 by the National Expert Committee on Industrial Foundations identifies high-precision pressure sensing elements, wide-temperature-range pressure sensors, robotic force sensors, and other such components and devices as key products and technologies that China urgently needs to break through.

▲ The “Five Foundations” of Industry—In the field of instruments and meters, there are a total of 37 “Basic Components and Devices,” of which 23 involve sensors, and 3 closely match the R&D products of SunoMeng.

The Hidden Crisis Lurking in the Blue Ocean of Robotics

Research on compliant control for robots is one of the hot topics in the field of robotics, with frequent breakthroughs and a wide variety of implementation approaches. These include schemes based on current-sensing force measurement as well as vision- and algorithm-based approaches. However, compliant control for robots that relies on torque sensors (torque transducers) to detect external forces is more sensitive and precise. It is also currently the earliest researched, most widely used, and most successfully applied approach among force-sensing systems.

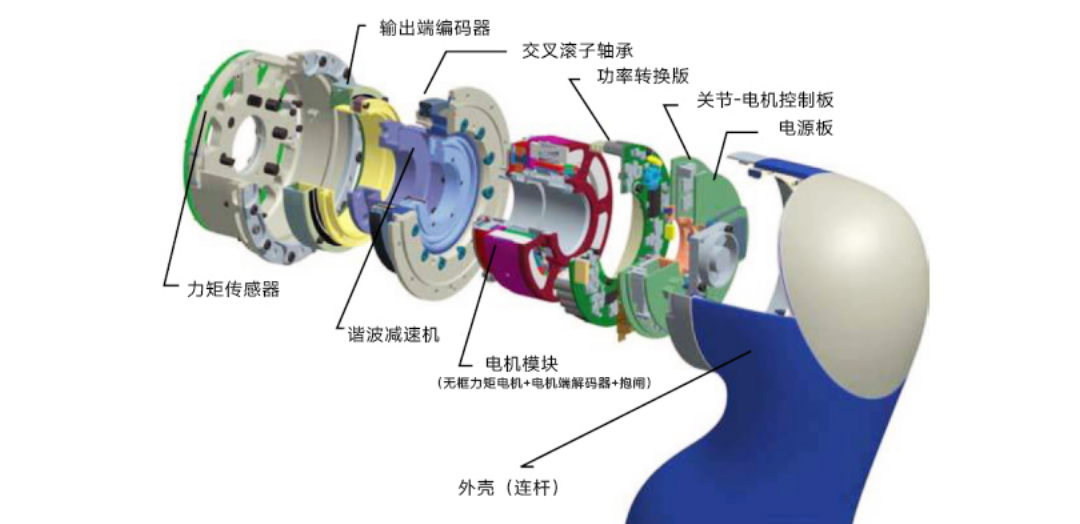

Currently, torque sensors are primarily integrated into the joint modules of collaborative robots. The emergence of collaborative robots has given rise to a new model of industrial automation, and the application of high-performance torque sensors has significantly enhanced the safety, ease of use, and intelligence of these robots.

Collaborative robots often feature highly systematic and integrated designs, with increasingly intelligent and lightweight operation. They can be safely and quickly deployed alongside humans in the same workspace, while also becoming smaller in size. A six-axis collaborative robot consists of six joint modules, each capable of achieving motion along all six degrees of freedom in space. Each joint module integrates components such as a driver, encoder, motor, harmonic reducer, and torque sensor. The torque sensor precisely measures both the magnitude and direction of the load torque during joint movement, making it a core component for the robot’s compliant control. Typically, these sensors are positioned at the end effector and on the joints of the robotic arm. A six-axis collaborative robot equipped with torque sensors can immediately stop upon encountering a person or object, thereby preventing any potential harm to surrounding objects and people.

▲ Robot joint module

Collaborative robots represent the fastest-growing segment within the robotics industry. According to a report by market analysis firm BIS Research, the global collaborative robot market was valued at approximately US$674.9 million in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 28% by 2025. To date, collaborative robots have been widely adopted across industries such as automotive, manufacturing, pharmaceuticals, and electronics, playing a key role in various automation processes—including machine maintenance, assembly, finishing, inspection, packaging, and palletizing.

However, almost no domestic manufacturers produce sensors that can endow robots with a sense of touch. For years, most Chinese sensor companies have focused primarily on gas, flow, temperature, and pressure sensors, and even fewer possess the capability for independent production. The current industry situation is that virtually no sensor manufacturers are engaged in the research and development or production of tactile sensors. Beneath the booming market for collaborative robots lies a significant hidden crisis.

From being “choked” to becoming an industry “leader”

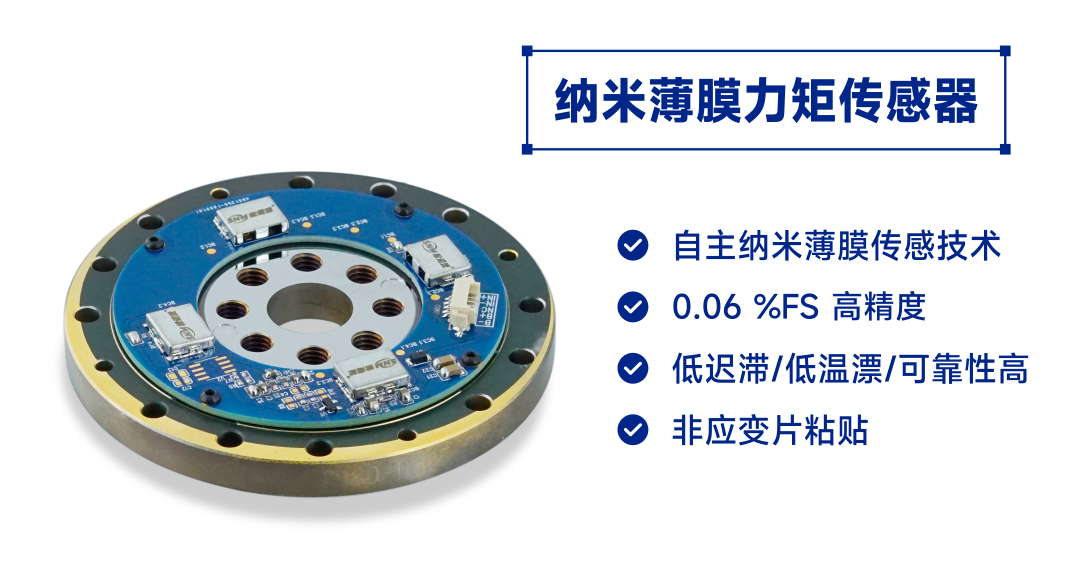

In 2021, Suno-Meng launched a torque sensor developed and manufactured domestically based on nanofilm sensing technology. After rapid iterative improvements, the sensor’s accuracy was boosted to 0.06% of full scale, marking a breakthrough leap in China’s torque sensor technology.

▲ SonoMai Nano-Film Torque Sensor

As early as 2017, the SunoMeng’s early R&D team proposed the idea of applying nanofilm sensing technology to torque sensors and began working on design and verification.

In the past, strain-type torque sensors typically employed an adhesive bonding process, in which strain gauges were affixed to an elastic body. This approach has the advantages of low cost and rapid mass production; however, it also suffers from inherent drawbacks. When the torque applied to a collaborative robot’s joint acts on the torque sensor’s elastic body, the latter undergoes deformation. Yet, the presence of the adhesive layer leads to stress attenuation, and over prolonged operation, the adhesive itself can degrade. Consequently, strain-based torque sensors using the adhesive bonding method often exhibit significant hysteresis, creep, and aging effects. Moreover, the single-axis, rapid alternating positive and negative torque sensing mode commonly used in joint torque sensors further exacerbates these shortcomings.

However, the nanofilm torque sensor, which is also based on the strain principle, fundamentally addresses the shortcomings of conventional adhesive-type torque sensors.

The nanofilm torque sensor is manufactured using an ion-beam sputtering process in a high-cleanliness, vacuum environment. In this process, a target material and a metallic elastic element are bombarded by an ion beam, followed by the slow deposition of a strain-resistance layer that “grows” gradually, achieving atomic-level fusion among the strain resistance, the metallic elastic element, and the protective film. This is the key feature that distinguishes the nanofilm torque sensor from conventional torque sensors. By eliminating the adhesive layer at the source, this technology avoids the defects—such as creep, hysteresis, and aging—that typically arise from traditional bonding processes. As a result, the torque sensor can maintain long-term stability even under frequent joint rotations, with an accuracy reaching as high as 0.06% of full scale (FS).

The application of nanofilm sensing technology has significantly enhanced the accuracy and stability of torque sensors for collaborative robot joints, driving innovation in China’s torque sensor technology and successfully placing China on the global cutting-edge stage for torque sensors. This breakthrough has also addressed another critical “bottleneck” technological challenge facing China.

The integration of high-precision torque sensors endows collaborative robots with the ability to accurately sense external torque loads, laying a solid foundation for the subsequent development of even more sophisticated interactive capabilities in these robots. The long-standing situation of heavy reliance on imported torque sensors is now changing; breakthroughs in domestically produced high-performance torque sensor technology will strongly safeguard the security of China’s industrial upgrading and drive the development of China’s sensor industry. In the future, as an increasing number of high-performance sensors become domestically produced and replace imported ones, our seamless, safe, natural, and smooth interactions with robots will become the new norm. |

Previous:

Contact Us

Address : No. 18 Xiangtai Road, Liuyang Economic and Technological Development Zone, Building A5, Changsha E Center.China

Phone : +86-400-002-1378

Email : business@chnsnm.com

Sales : +86-173-7371-3251 (Mr. Zeng)